A full range of

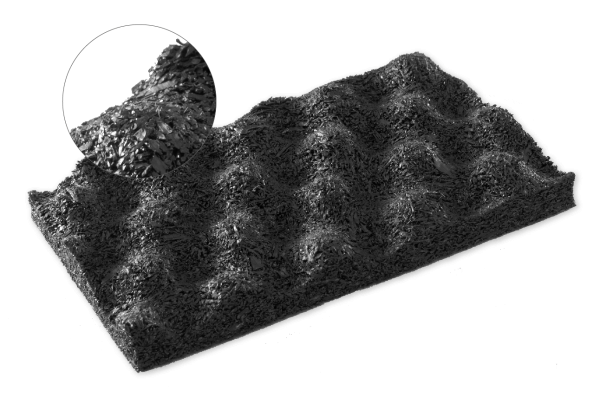

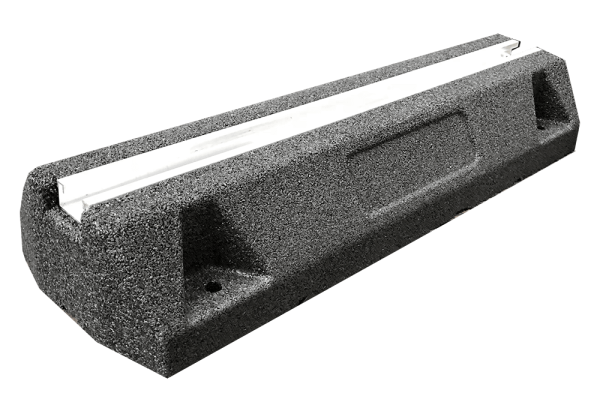

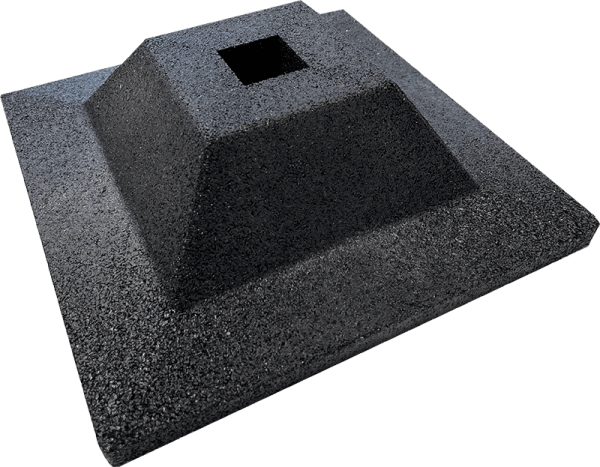

high performance acoustic mats

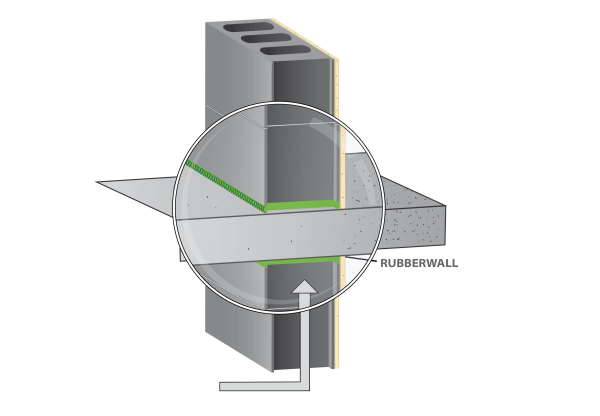

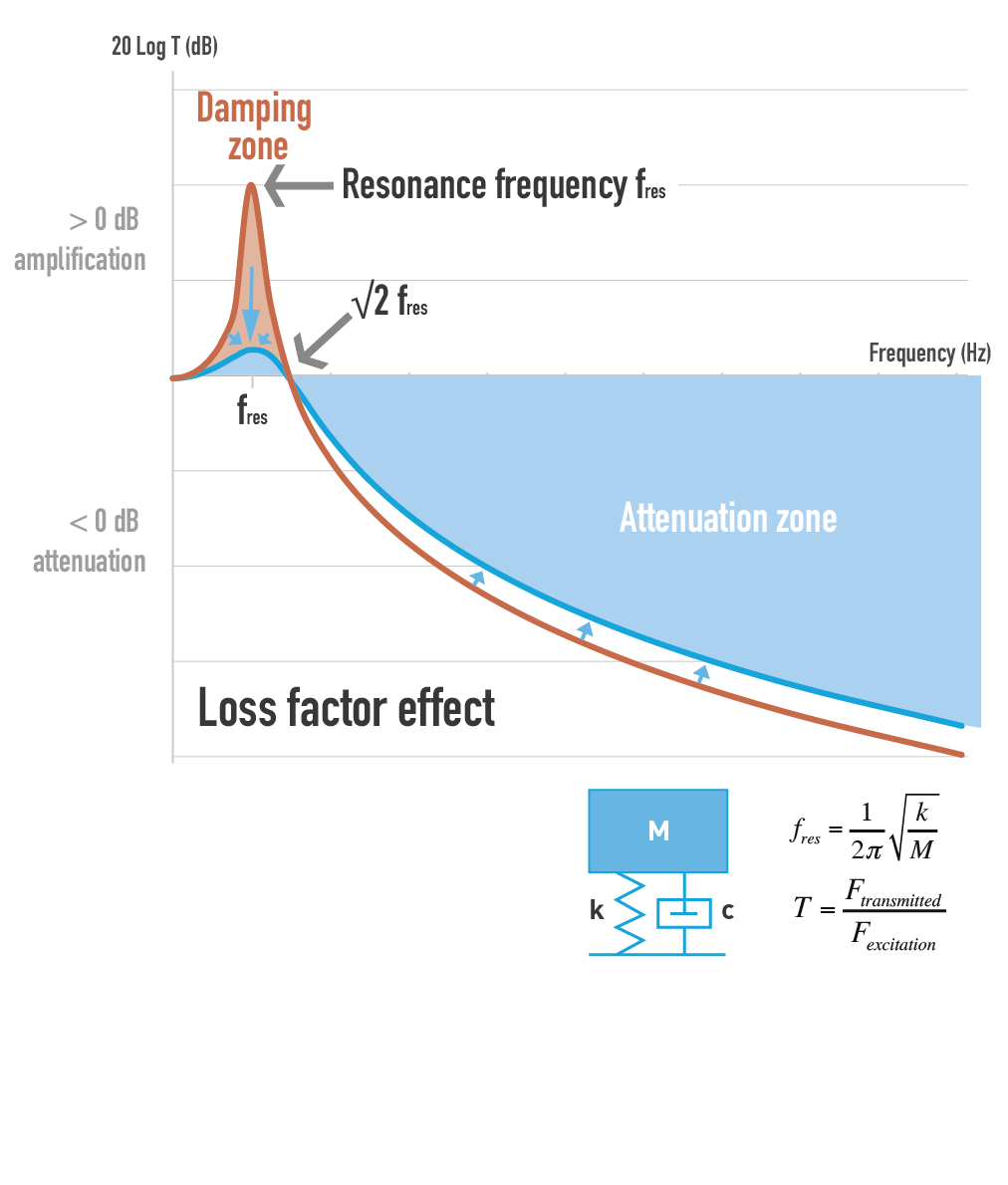

Designed to isolate screeds from the main structure of the building, reducing impact energy generated by general footfall.

All products made from Natural Recycled Rubber